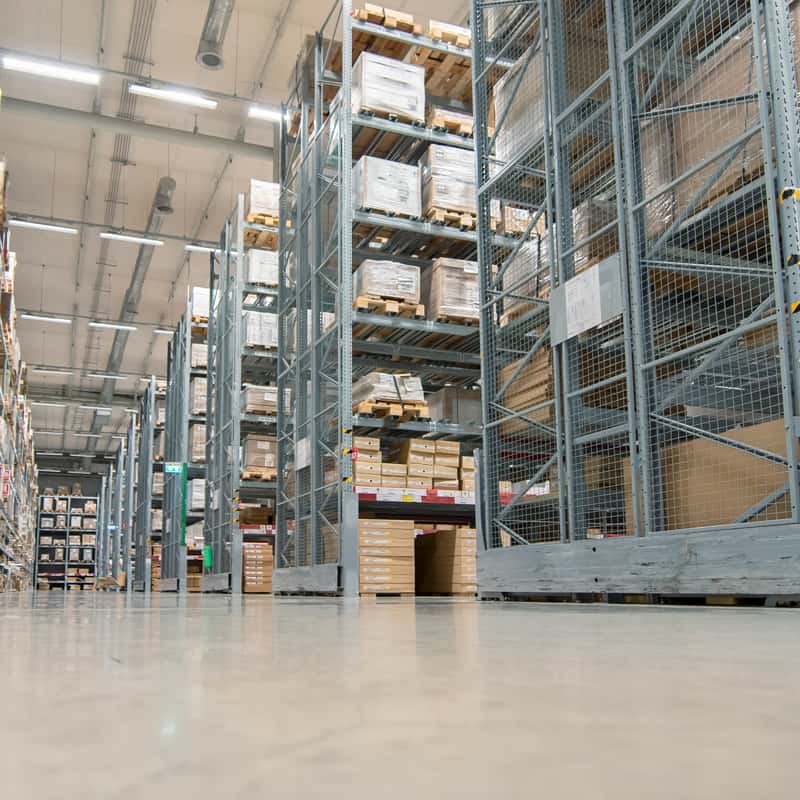

INDUSTRIAL CONCRETE FLOOR COATING

For your garage, plant or warehouse

If the floor of your garage, plant or warehouse needs a new, resistant finish, you’ve come to the right place.

B-PROTEK specializes in all types of concrete floor coatings. Regardless of the condition of the floor, we can recommend an excellent and long-lasting solution.

Are B-Protek’s Industrial Floor Coating Products Suited for My Company?

Specific production needs can be met by using a variety of our fast cure, low odor formulations. Our unique high-performance floor coatings protect against high temperatures and thermal shock.

All these products are low in maintenance and provide the ultimate in safe and clean work environments. Additionally, they can withstand frequent cleaning, high impacts, and vehicle traffic.

Our industrial floor coatings can be simply applied to most floors and meet different needs and budgets. Also, we provide coating services for exterior surfaces, as well as loft and basement floors.

The following coatings are best suited for industrial applications:

- Epoxy Solids: firmly established as a solid and durable solution, and is ideal for garage and industrial floors. In addition, epoxy requires no maintenance.

- Clear Epoxy Concrete Coating: this type of coating provides an alternative to periodical polishing, and is far less expensive in the long run.

The Advantages of an Epoxy Industrial Floor Coating

Our epoxy flooring coating systems have a number of properties and benefits:

- Waterproof, non-porous and seamless : Easy to maintain over the long term. The high density product stops dirt from penetrating the pores. The same goes for water, which will avoid water damage in case of flooding or leak. Generally speaking, a seamless surface means that the life of the floor will likely outlast that of the surrounding walls. It can take a heavy beating and resists most industrial wear and tear.

- Stain resistant: smooth and homogenous, any liquids or substances will remain on the surface, preserving the concrete underneath

- Resistant to chemicals : the high level of tolerance enables high impact cleaning without affecting the durability of the coating. As for spills, it’s okay if you don’t clean them immediately, you have a few days to clean the product without impacting the coating. If you regularly use a chemical product which you have doubts about, let us know. We can inform you on whatever limitations or precautions to take with the industrial floor coating.

- VOC free : the coating is 100% solid and solvent-free, therefore poses no health and respiratory issues. It doesn’t give off an undesirable smell during application or drying.

- Non-slip: This can vary depending on your needs – a protective layer can be added to give texture and increase its resistance to scratches. Aggregates may be included to give the industrial floor coating better grip.

- Antistatic : Avoid the accumulation of static electricity caused by friction. Low intensity electric charges can cause sparks, which in some sectors are vital to keep under control.

- Light reflecting: The shine brought by the end-product reflects any natural or artificial light in the space, giving it even more brightness without increasing your electricity bill.

- Mold and bacteria resistant: waterproof and seamless, the coating stops the development of bacteria and mold caused by ingress of water.

- Scratch resistant: having a scratch-resistance similar to a crystal varnished timber floor, epoxy’s advantage is that it is colored from within, which means the industrial floor coating will not change color even if scratched. Furthermore, there are a number of simple solutions to solve the issue:

- Urethane protective coat : A matte or satin coat can be applied as a final layer. This will help protect against scratches and increase the coating’s durability. Aluminum oxide can also be added, to make it even more grippy and non-slip.

- Floor wax: after final drying, you can apply a standard floor wax to the industrial floor coating. This will preserve the shine of the epoxy over the long term, as well as protect it. It’s a cheaper solution, but will require annual applications.

- Polishing: if after a few years you find the coating has lost its shine, micro-scratches have appeared, it is possible to simply polish the coating to give its original sheen back.

How is the Industrial Concrete Floor Coating Installed?

We have more than 10 years of experience, and have become experts in our field. We can assure you will get the results you are expecting, and more. Our customer service is available to you at all times to answer queries and dissipate any doubts you may have.

The first step consists of a visit from our representative to fully understand your needs and requirements. They will advise you on the different solutions available, along with their respective budgets. Thereafter, they will establish an estimate for the work, and how long it will take. We always send our clients a written and detailed quote, and clear up any doubts before proceeding.

Step two, once you have decided what product you want, we set a date for the industrial floor coating application. Flexible about when you can free up your floor while minimally impacting your operations.

Our team will start by using a diamond grinder to mechanically rough up the surface. Then, depending on the condition of the floor, they may apply a self-leveling epoxy to eliminate any remaining damage. If there are cracks, a grinder is used to open them, and a quick-drying repair product is applied.

When the team is satisfied with the preparation, the industrial floor coating of your choice is applied and given time to dry properly. After this, you may move vehicles, install shelving and heavy machinery as you please, knowing that your floor is the most resistant it will ever be.

Call on B-PROTEK for your industrial floor coating!

B-PROTEK has the expertise needed for finishing your industrial concrete floors. We have everything required to complete your project successfully:

- Highly-skilled, professional workers

- The latest high-performance equipment

- Superior, industrial-quality products

- High standards for quality and health and safety

When you decide to do business with B-PROTEK, you will immediately get the feeling that you’re being taken care of. We offer the following products:

- 100% solids color epoxy in various colors

- 100% clear epoxy

- 100% polyurea polyaspartic floor coating with vinyl flakes

- Safety lines

- Anti-slip coatings

Making changes to your installations and floors will bring an immediate positive impact to your workplace. Objectively, the interior space will be brighter, and health and safety performance will be improved.

More subtle, but notable, will be the rewarding feeling for you and your employees; visitors and customers will also be impressed. All in all, the investment in time and money will be a worthwhile effort.

Positive impacts

After applying our concrete floor finish, you will immediately see a positive impact on your business. The interior space will be brighter, your health and safety performance will be world-class and your employees will have a rewarding workplace. Your visitors and customers will also be impressed. Making these changes is far from relaxing and requires a certain investment. But every morning, when you make your rounds of the plant, you’ll tell yourself that the effort was worthwhile.

REQUEST INFORMATION

![]()

When it comes to floor quality, we like to believe there is no ceiling.

“Great company with the concern of a job well done. Professionalism A-1.”